- Home

- >

- Products

- >

- Electric Vehicle Parts

- >

- Smart Trailer

- >

- Smart electric trailer system for semi truck or heavy truck including drive system & load-bearing system & transmission system

Smart electric trailer system for semi truck or heavy truck including drive system & load-bearing system & transmission system

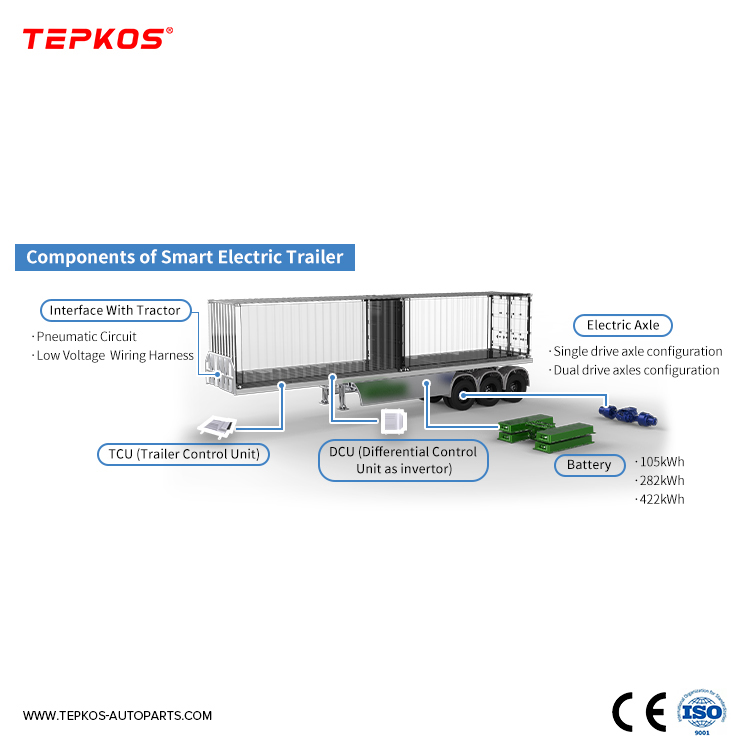

Smart drive trailer: based on the distributed drive system (including drive system + load-bearing system + transmission system), with a specific VCU for smart drive trailers as the execution. The brain carries out electric and intelligent transformation of traditional trailers from the dimensions of safety, reliability, economy and other aspects.

Product Description

What is Smart Electric Trailer?

Traditional trailers don’t have any power source on it. Smart electric trailers adopt electric power train and smart control technology including electric axle, battery, TCU (Trailer Control Unit) to transform traditional trailer to smart and electric one. The goal of application of smart electric trailer is to save energy and reduce emission.

Functions of Smart Electric Trailer

Power supplement: Auxiliary power for acceleration, climbing, etc.

Slow down function: Replaces retarder and can recover energy

Smart recycling: Electric braking and traditional braking are fully decoupled

Power mode:Optimal power and torque adaptation control

Core Technology

Core Technology-Adaptive Strategy

-Adaptive Strategy

Adaptive with different types of tractor: Fuel, Electric, Hydrogen fuel etc.

Scenario Self-sensing: Road condition, vehicle condition, driving intention

Adaptive scenario algorithm: Power supplement / Slow Down Function / Smart Recycling / Power Mode

Core Technology-Distributed Drive

-Distributed Drive with Electric Axle

Wheel-side electric motor and DCU (invertor)

Strong Power Output

EMB (Electronics Mechanic Brake) Optional

Our Advantages

Significant weight reduction

Compared with the central drive, the system weight is reduced by 787kg, a reduction of 23.6%; compared with the motor-gearbox integrated bridge, it is reduced by 798kg, a reduction of 23.9%.

drive solution

The traditional mid-drive rear axle adopts a helical bevel gear structure. The forward and reverse tooth surfaces have inconsistent torque transmission capabilities, The reverse torque transmission capability is low, also the feedback braking capability of the motor cannot be fully utilized.

The distributed drive adopts parallel shaft cylindrical gear transmission. The forward and reverse gears are exactly the same, which can withstand 100% reverse torque and make full use of the feedback braking ability of the motor.

Stronger feedback capability and improved braking performance

Large feedback torque, brings more stability to the vehicle and shorter braking performances

With proactive security strategies, and some natural advantages

Equipped with EASR drive wheel slip, ESC body stabilization system, and electronic differential lock, there are no configurations. The anti-slip and escape performance on rainy and snowy roads is significantly improved through strategic control of the wheel motor electronic differential system, The vehicle is equipped with EASR/ESC safety configuration to improve the vehicle's passability, handling stability and safety.

Distributed drive greatly improves active safety, has stronger power, saves energy consumption, and lowers vehicle costs.

Adaptability: It can be customized and developed according to the train power and mileage, and can be flexibly grouped;

Adaptive control algorithm can adapt to any energy source, including traditional fuel engines, pure electrics, hydrogen fuel cells, etc.

Environmental friendly: The intelligent drive trailer system provides electric driving force and makes full use of the engine's high-efficiency zone and energy recovery during deceleration, which can effectively reduce the carbon emissions of traditional fuel vehicles;Active safety: Distributed active control can realize electronic drive anti-skid (EASR) and body stability control (IESS) to improve trailer stability and avoid trailer drift;

Optional EMB provides faster braking response and is deeply decoupled from air brakes, further improving vehicle safety and economy;Energy saving: It can increase the operating speed and improve operating efficiency; the road adhesion utilization rate is greatly improved, and tire wear is reduced.

Application Scenario

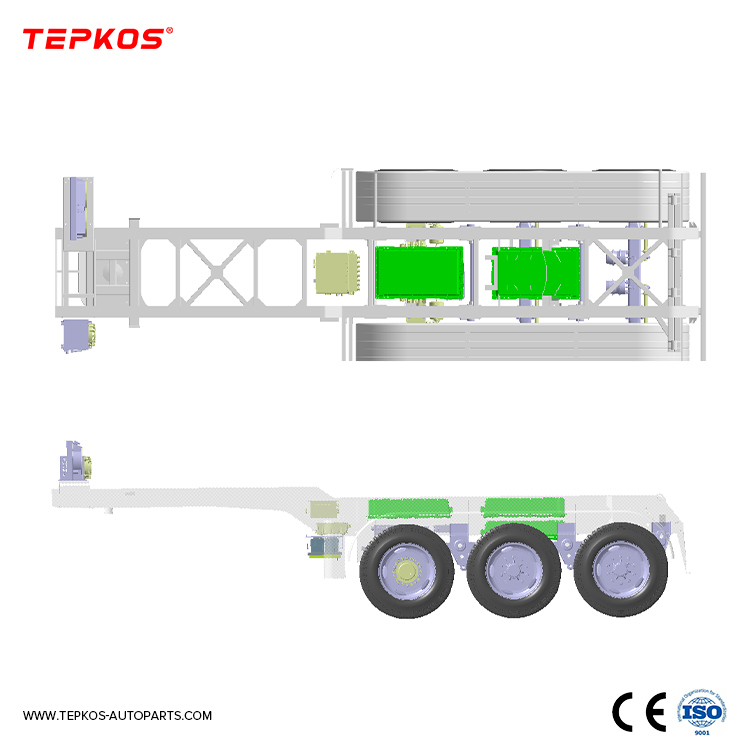

Case 1: Chongqing Smart drive Trailer Chassis Layout

The hybrid model (fuel tractor + samrt drive trailer) has a total vehicle power of 141kWh (105kWh). It is suitable for complex working conditions such as mountainous areas in Yunnan, Guizhou, Sichuan, hilly terrain, mining areas and factories. Noticed that the fuel saving rate is above 20%.

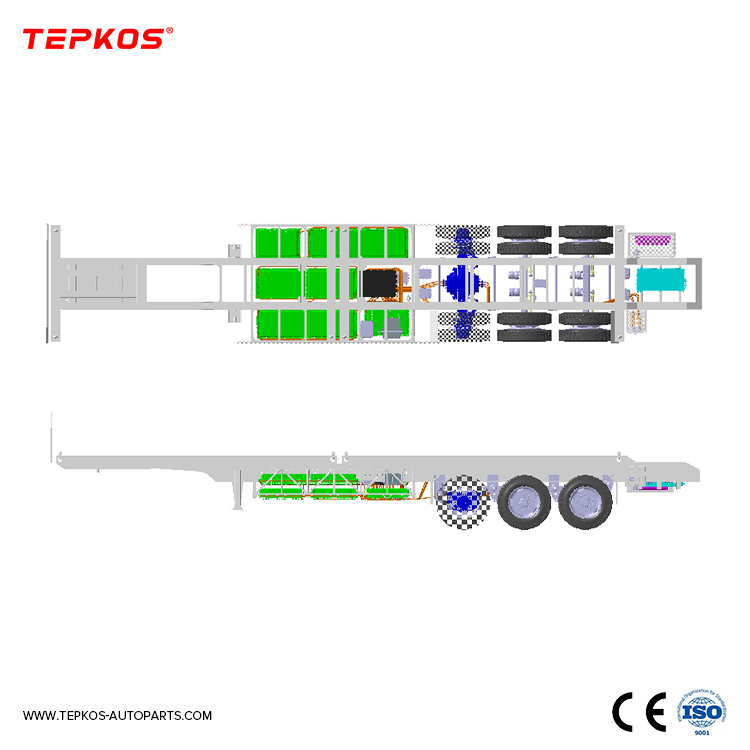

Case 2: Inner Mongolia Smart Drive Trailer Chassis Layout

Long-mileage smart drive trailer with power capacity of 472kWh (200~500kWh). Suitable for long-distance trunk logistics, mileage >500km. Suitable for long-distance trunk logistics, mileage >500km.

Certifications

Packing & Delivery

Get the latest price? We'll respond as soon as possible(within 12 hours)